We have developed part of the necessary engineering for Argentina’s new CAREM-25, a Small Modular Reactor. Additionally, we have contributed to the development of various Auxiliary Systems with a wide scope.

Read MoreDetermine the operating conditions of the systems in order to obtain the appropriate functionality in different operating states of the reactor.

Produce the basic engineering documentation, such as PFDs and P&IDs, descriptive memory reports, mass and energy balances, calculation memory reports, process data sheets, valves and special spares inventories.

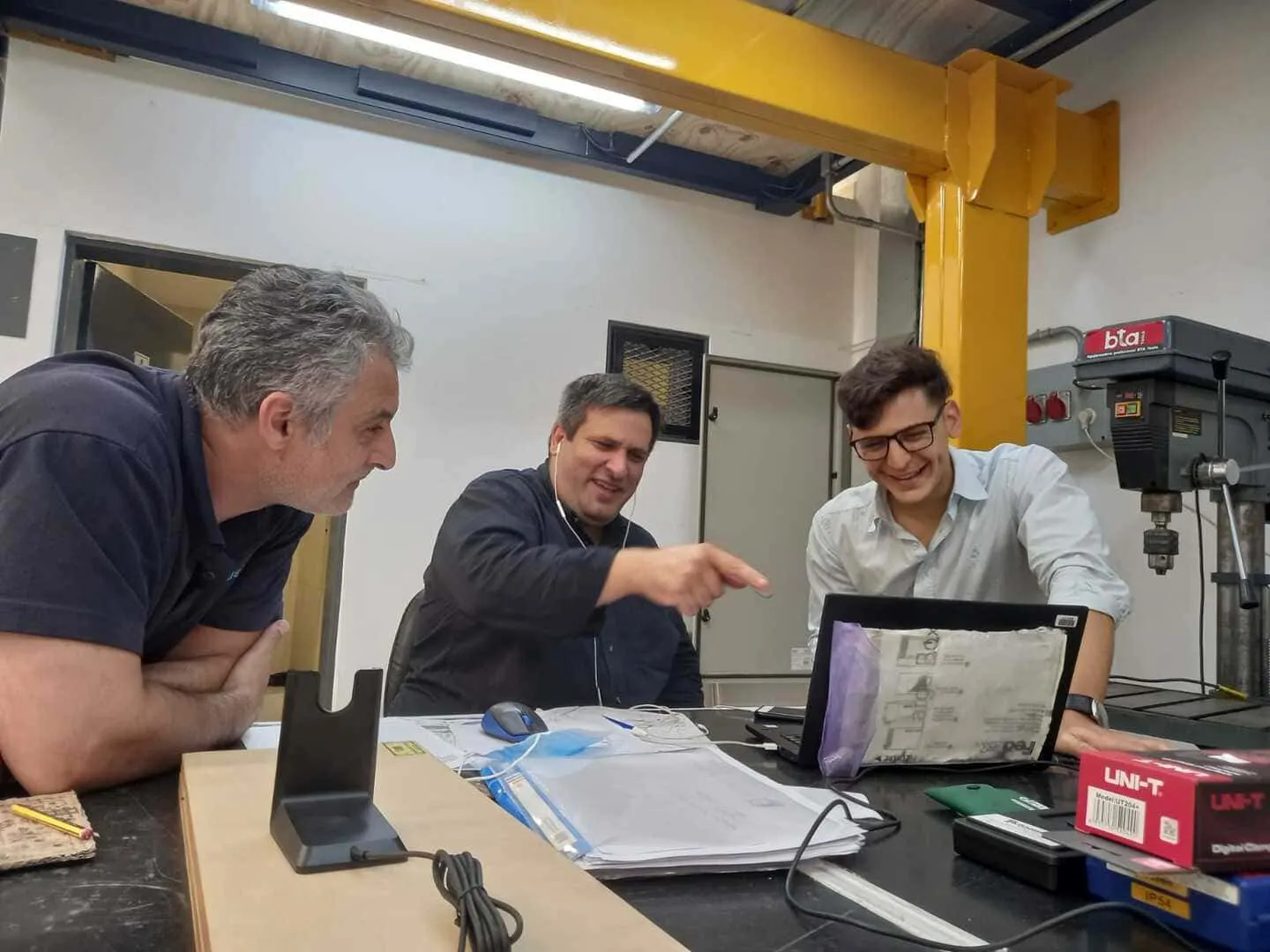

Cooperation among all engineering areas such as instrumentation, mechanical, piping, civil and safety, with the objective of creating a feasible design within the established conditions.

Selection of various equipment suppliers to achieve the optimization of the established systems and services.

Dynamic simulations are applied to verify the systems' proper functioning in the transition of their different operation modes.

Development of the documentation pertinent to the installation and wiring of the instrumentation equipment; instrument location drawings; piping; typical instrument mounting details and their support systems. Development of the list of mechanical, electrical and pneumatic materials; the technical aspects of purchasing specifications; data sheets; and the specifications of the selected instruments.

Read MoreDevelopment of the documentation pertinent to the installation and wiring of the instrumentation equipment; instrument location drawings; piping; typical instrument mounting details and their support systems. Development of the list of mechanical, electrical and pneumatic materials; the technical aspects of purchasing specifications; data sheets; and the specifications of the selected instruments.

Design and 3D modeling of all piping, standard and special components and supports, modeling of all static and rotating equipment, and metallic structures.

Design of equipment layout drawings, plant blueprints, details required for the correct execution of assembly works, stress analysis, bills of materials, and isometric drawings.

Design of pressure vessels included in the P&IDs, technical documentation of vessels, design specifications, precise technical specifications applicable to the project, quality levels and requirements for vessel manufacturing.

Development of the technical aspects of purchasing specifications, data sheets, general dimension drawings, associated instrumentation, inspection plans, painting procedure, shipping and storage procedure for rotating machinery and equipment.

Design of the detailed engineering containing all the necessary information so that the selected supplier is able to develop the documentation for manufacturing, assembly and storage of materials for metallic structures.