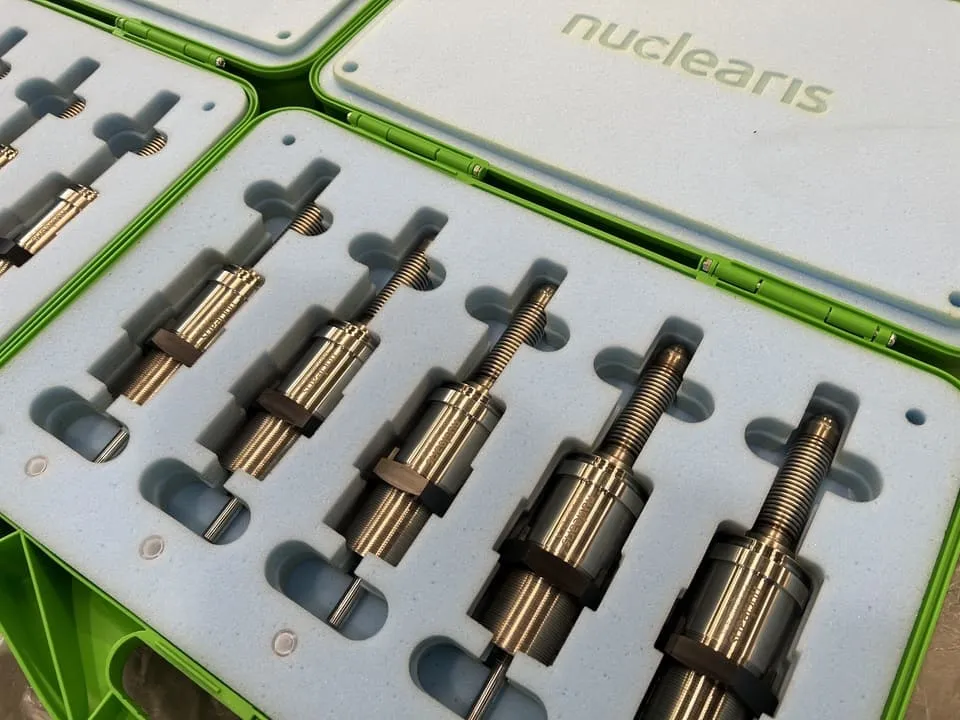

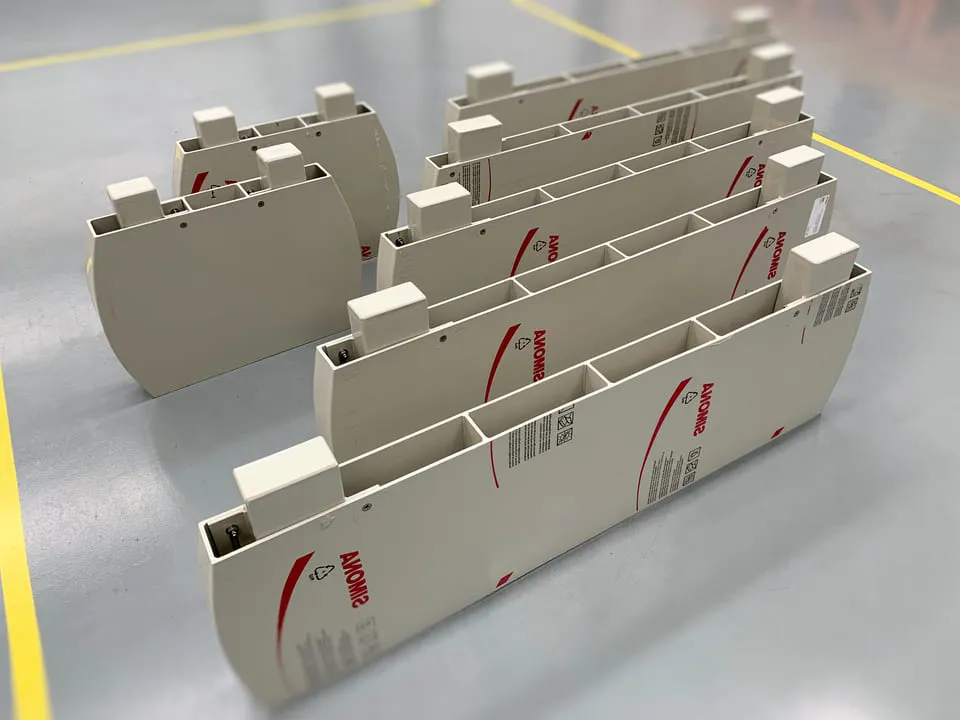

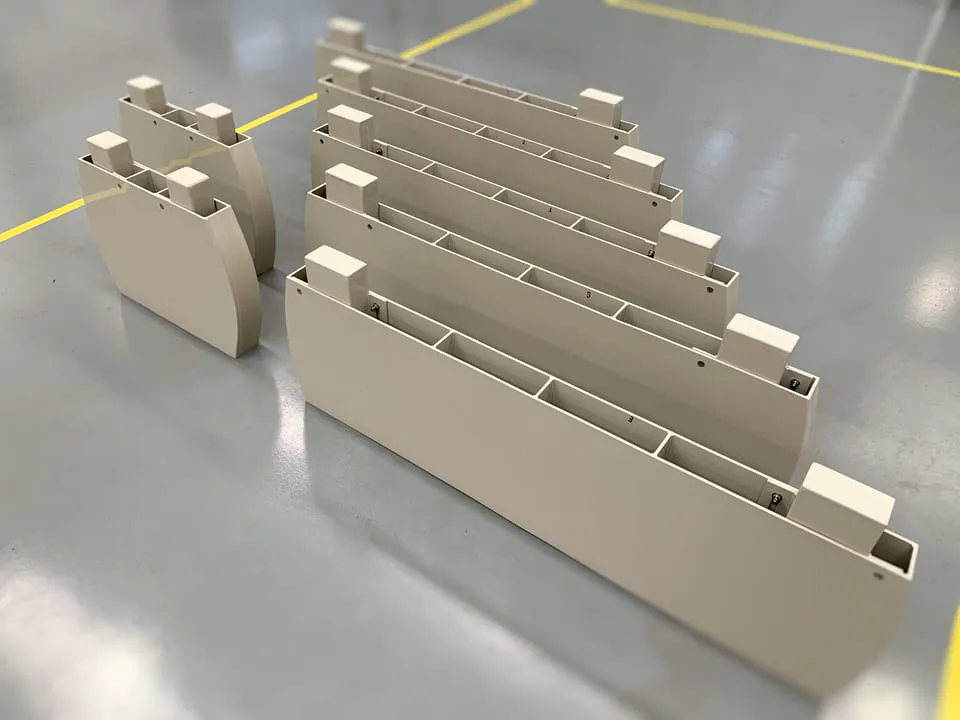

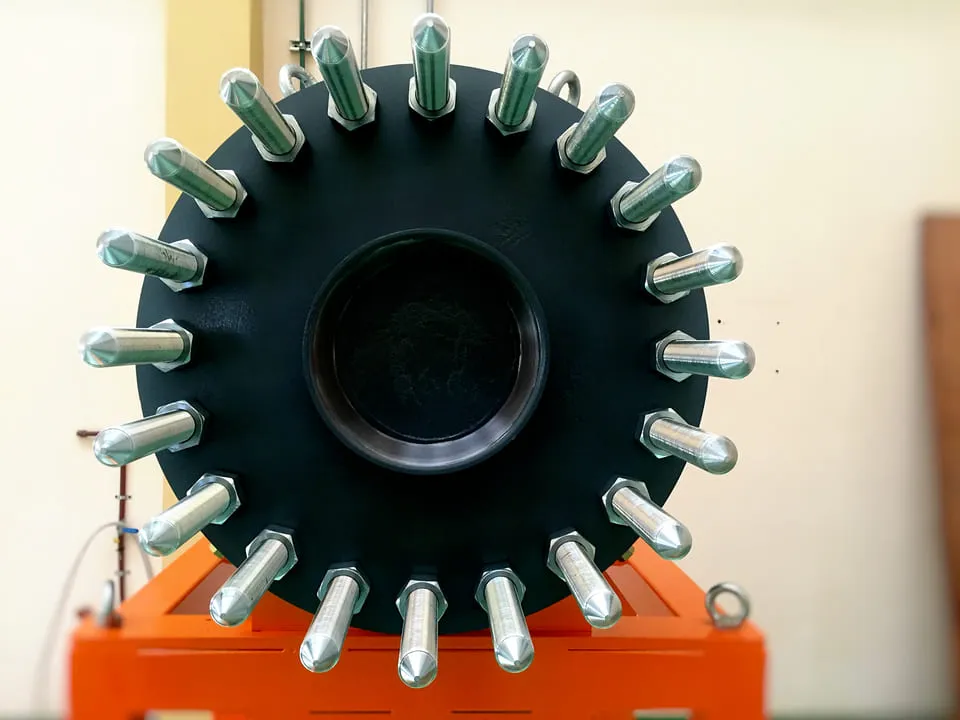

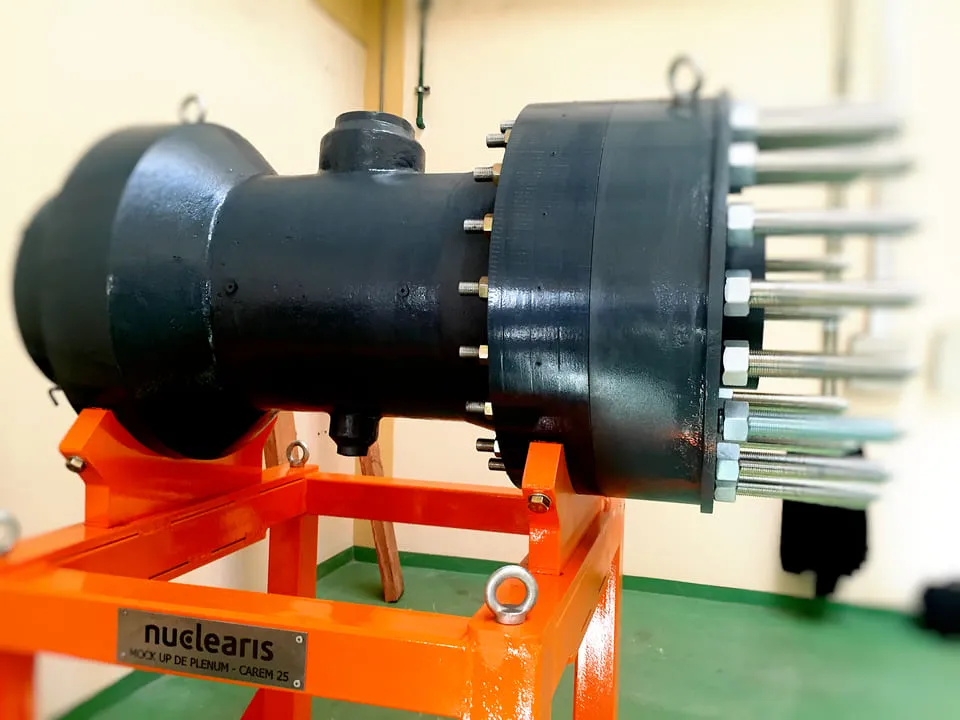

COBALT 59 SLUGS

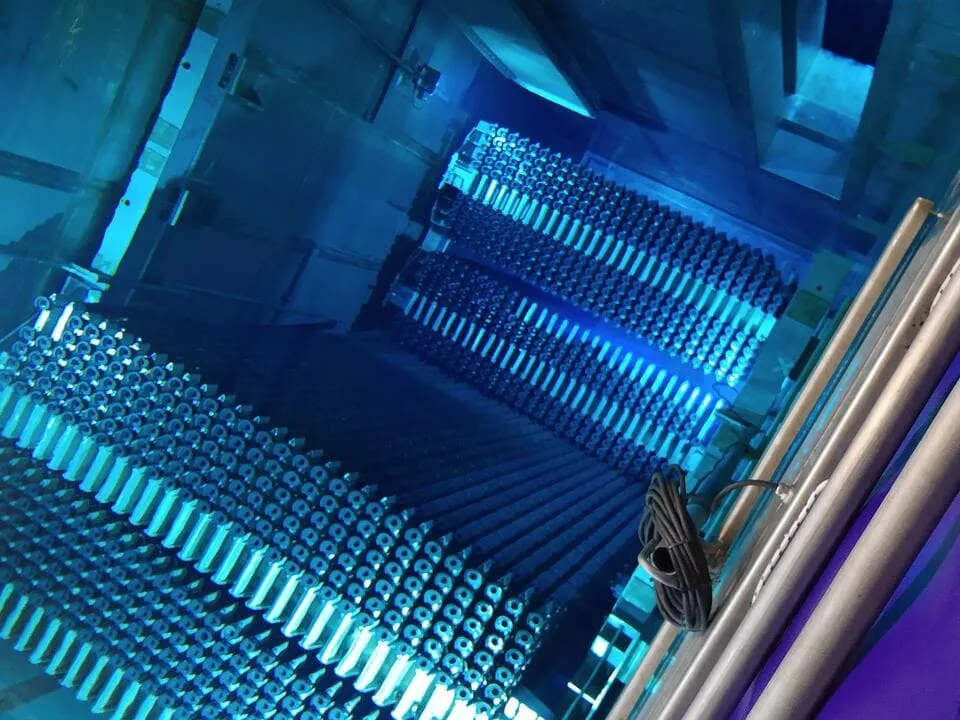

There are only 3 countries in the world that manufacture radioactive sources of Cobalt 60 used mainly for Radiotherapy (oncology) and other industrial applications. These countries are Russia, Canada and Argentina.

Read MoreCOBALT 59 SLUGS

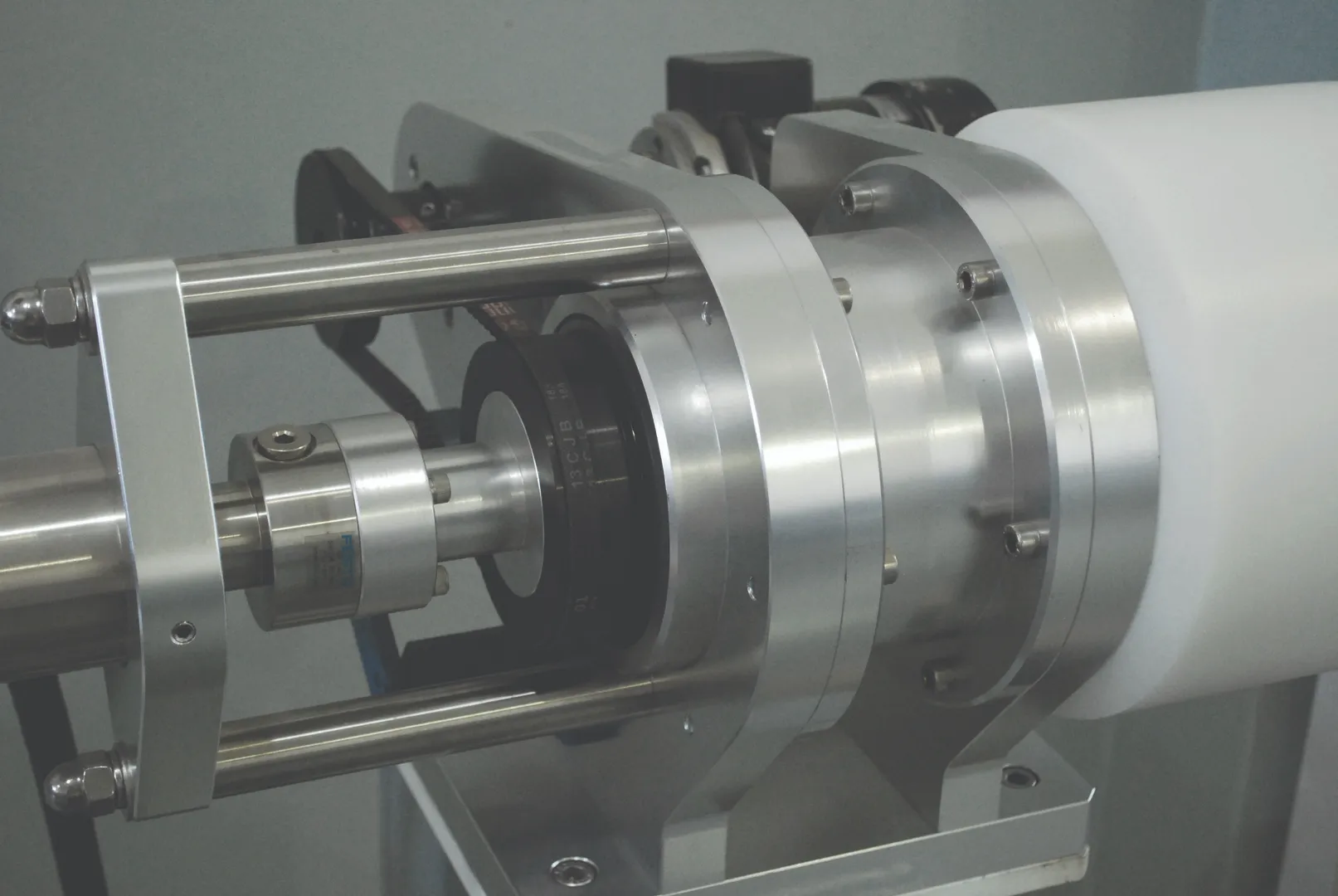

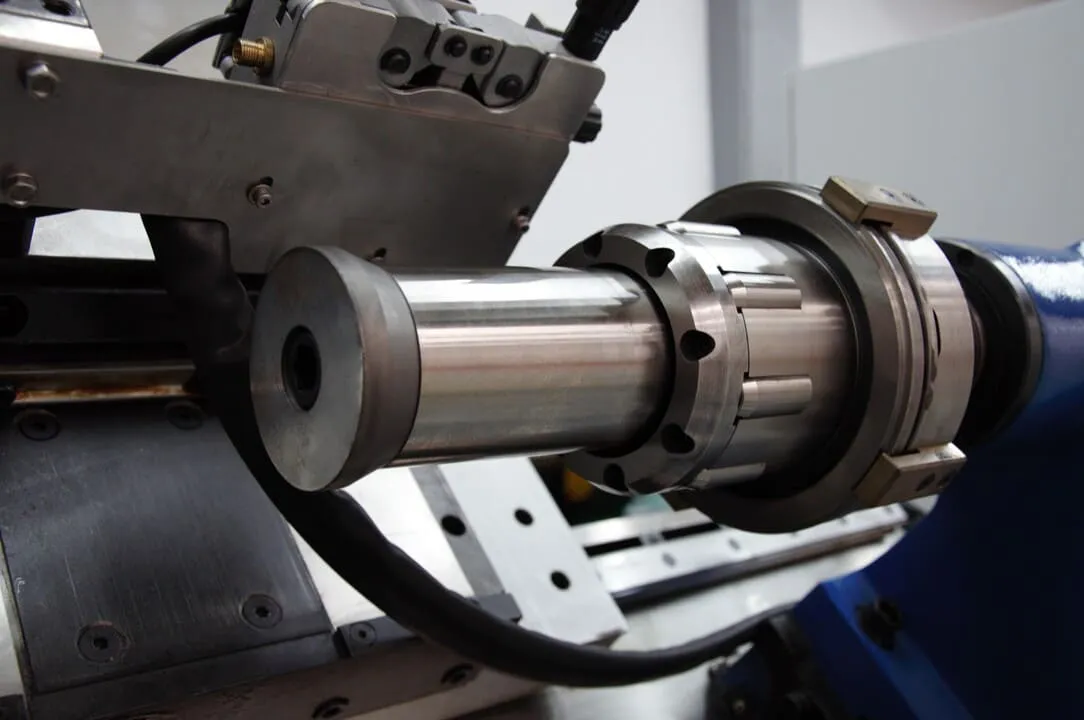

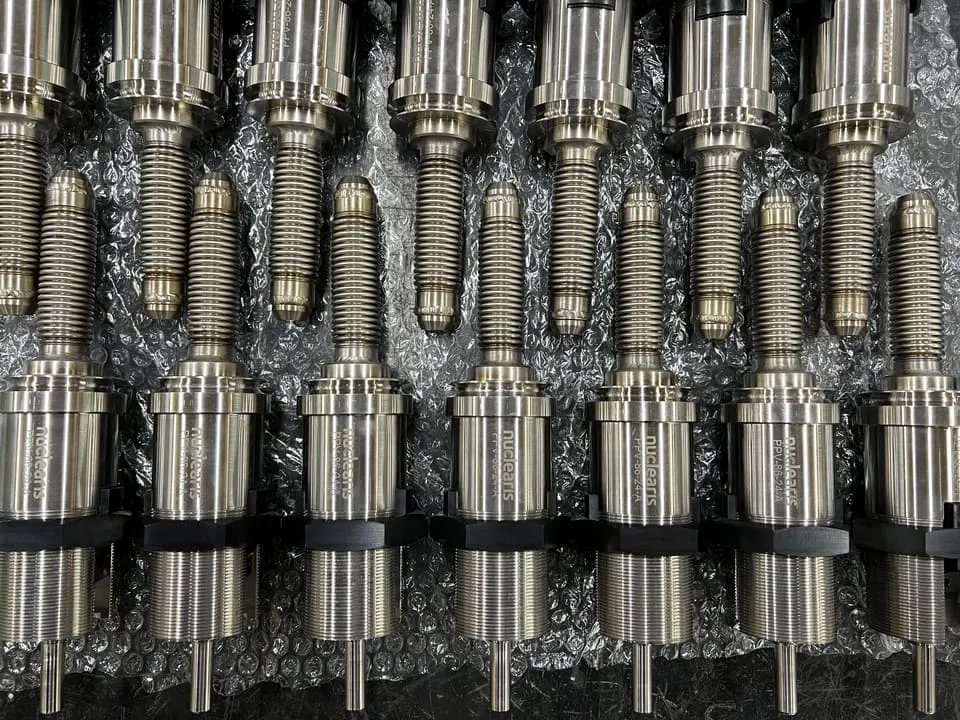

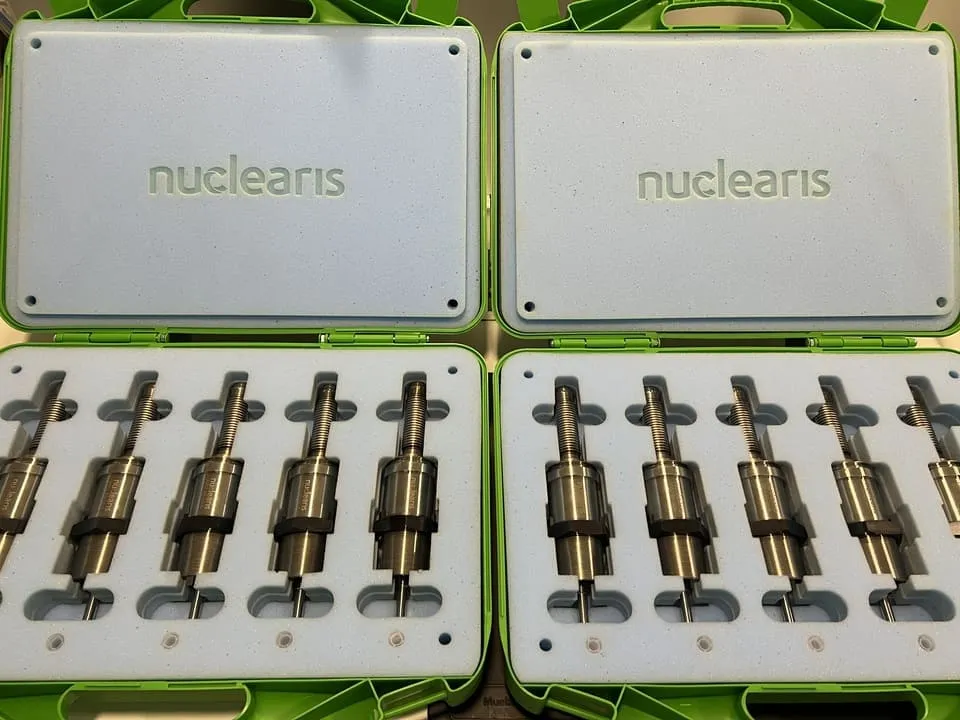

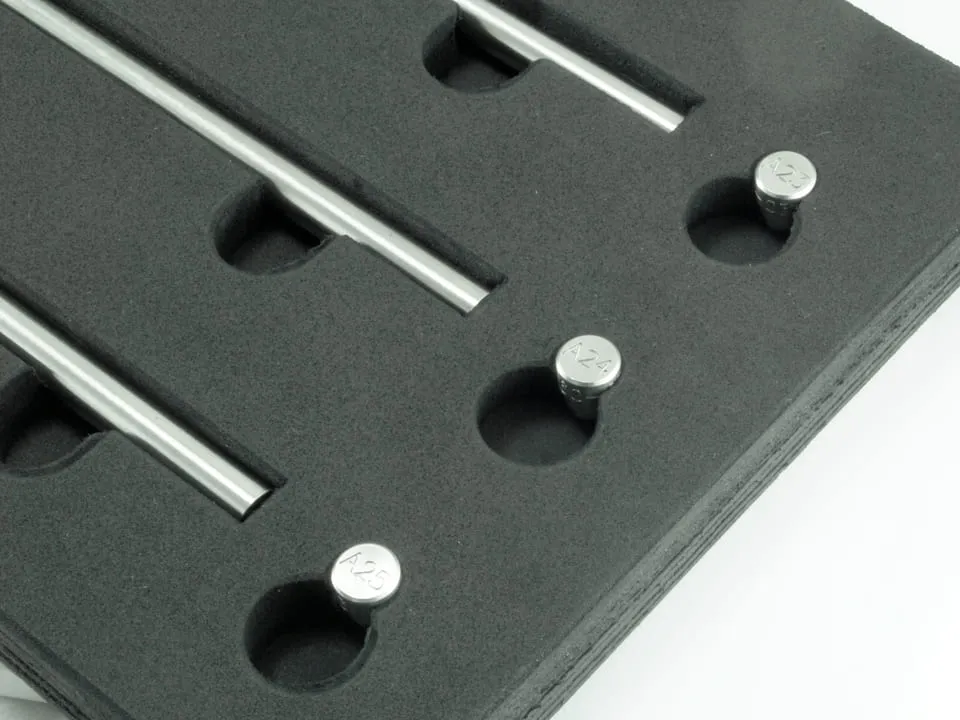

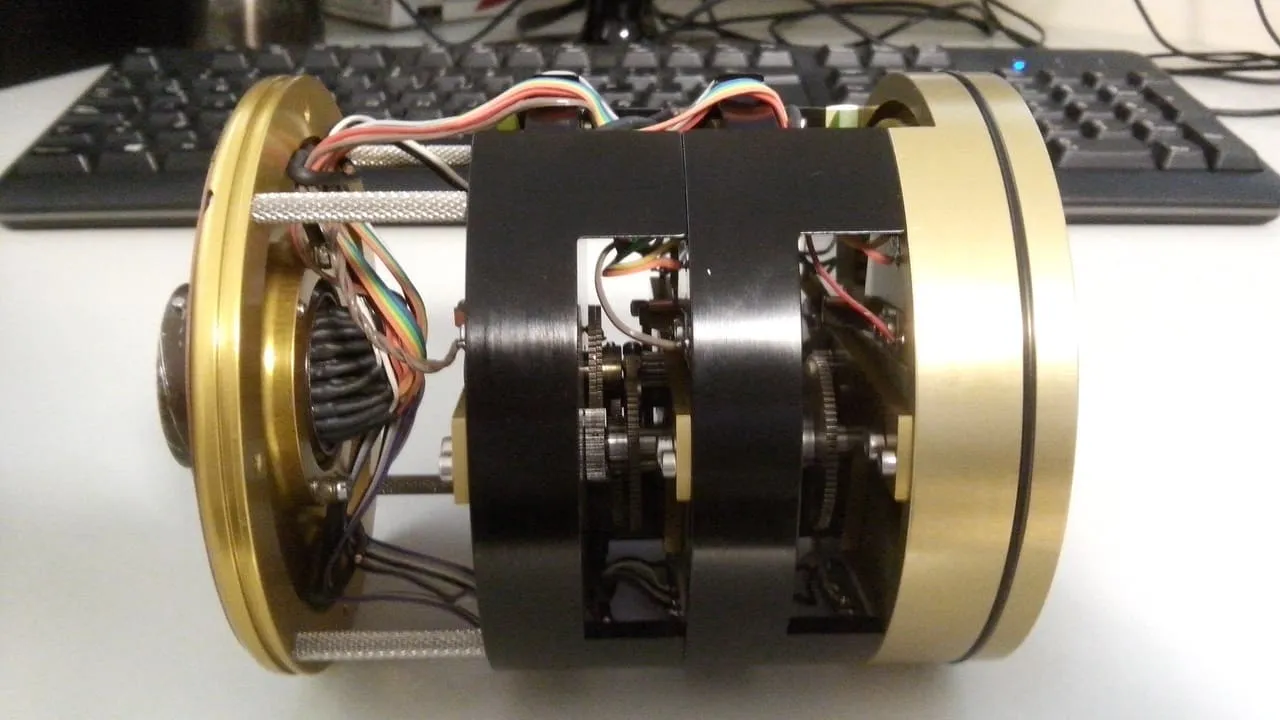

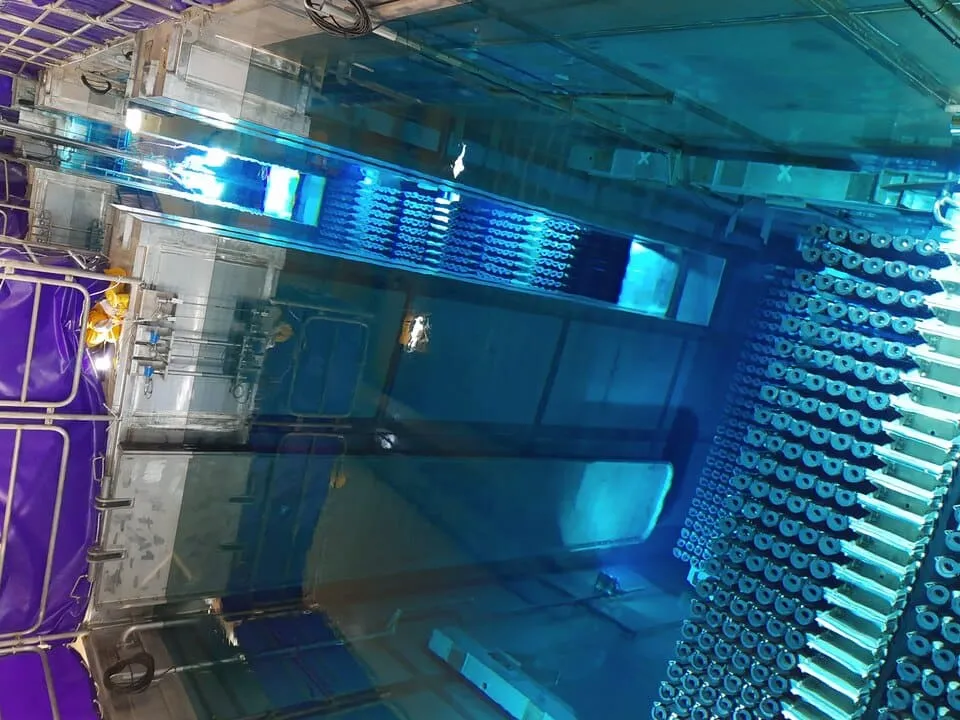

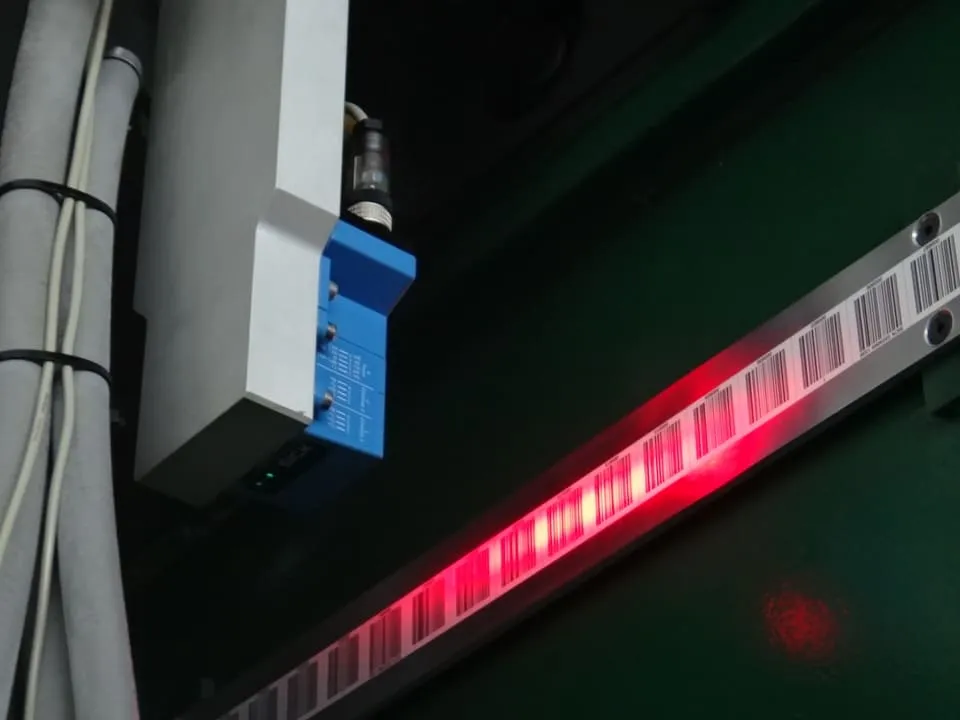

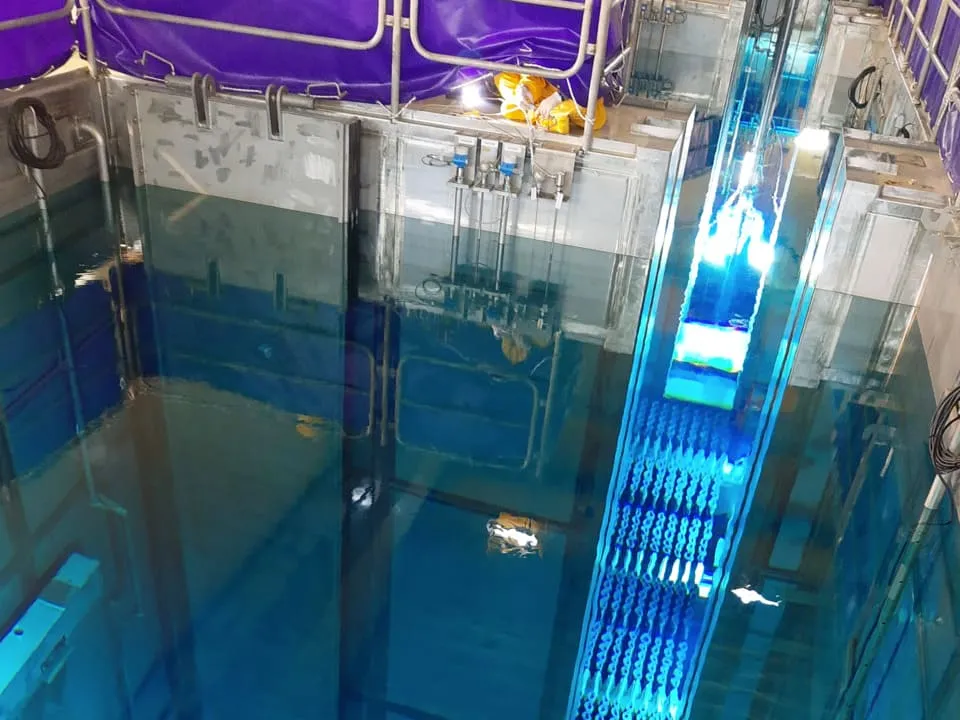

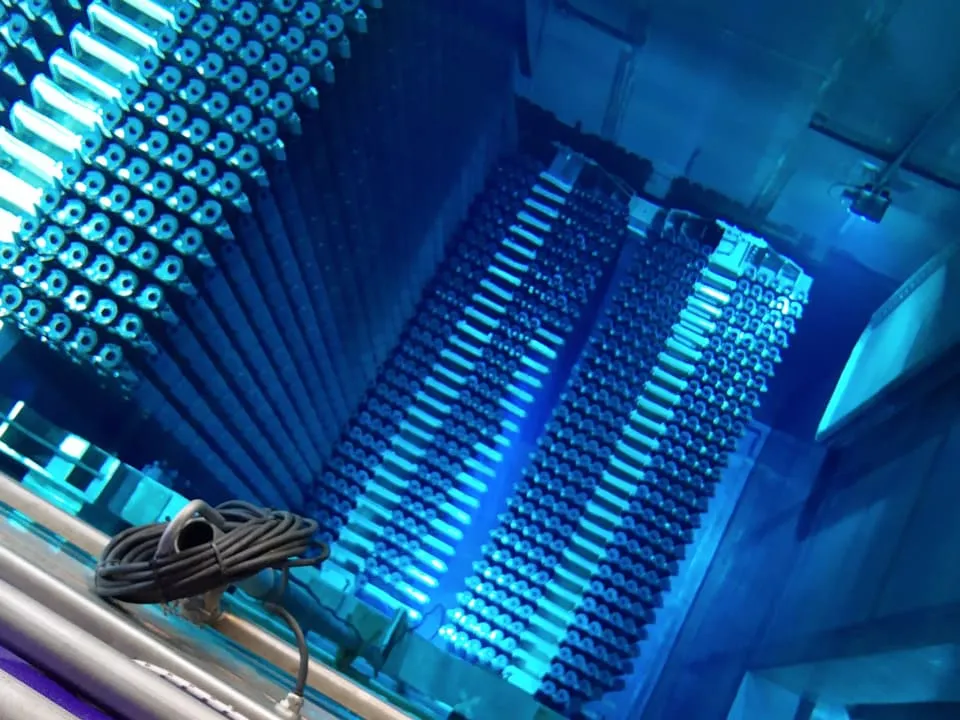

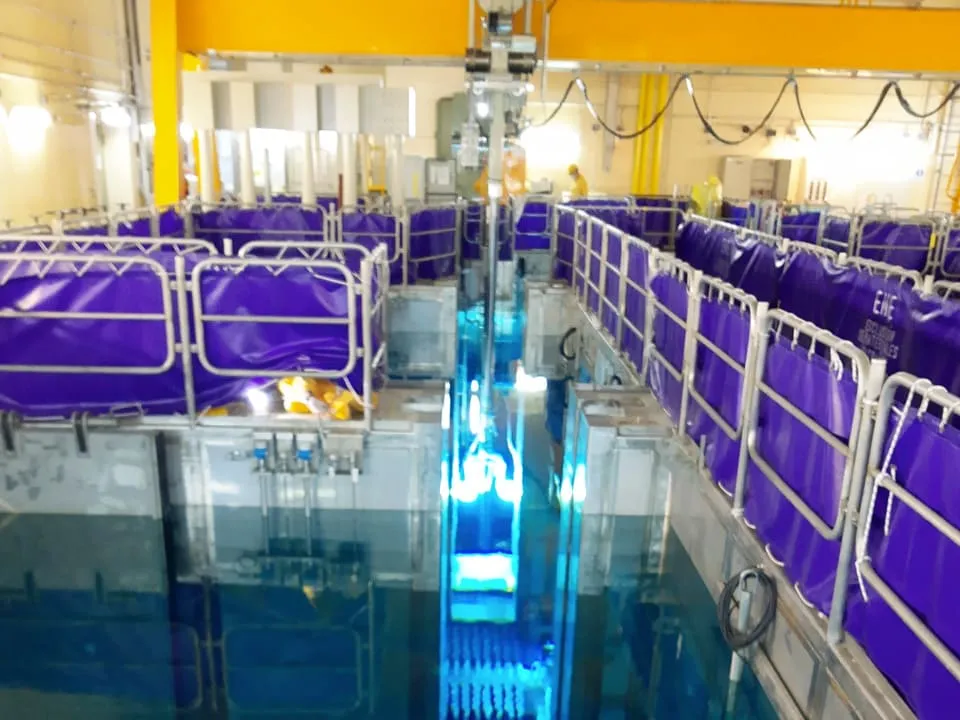

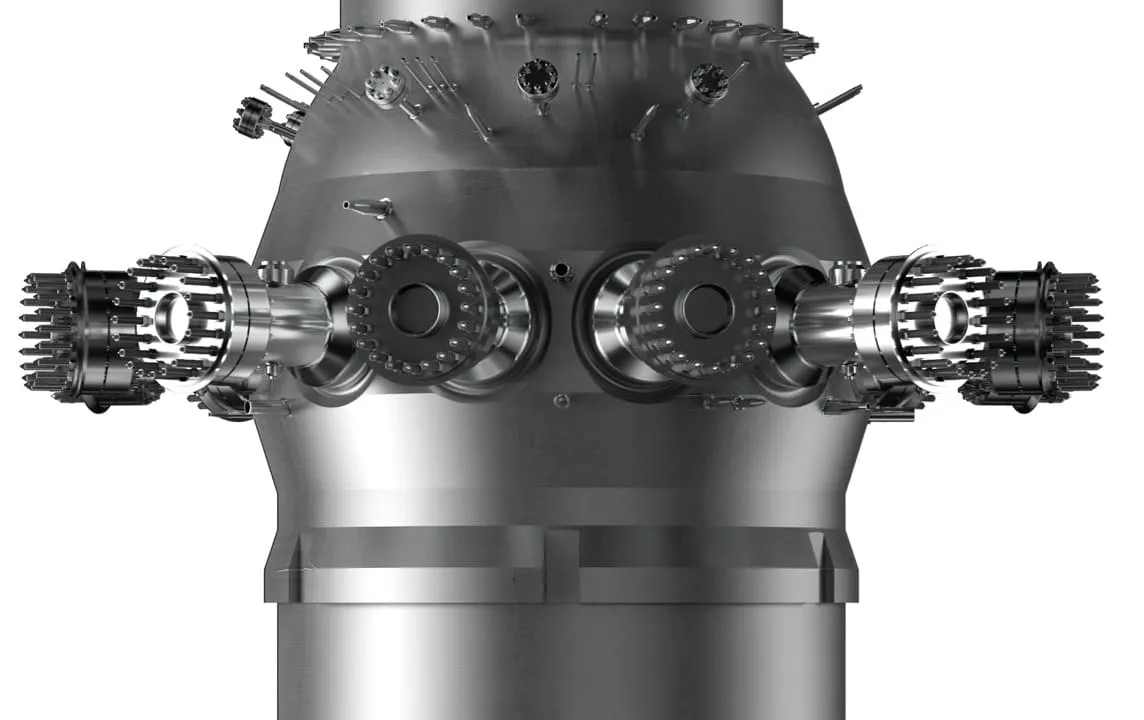

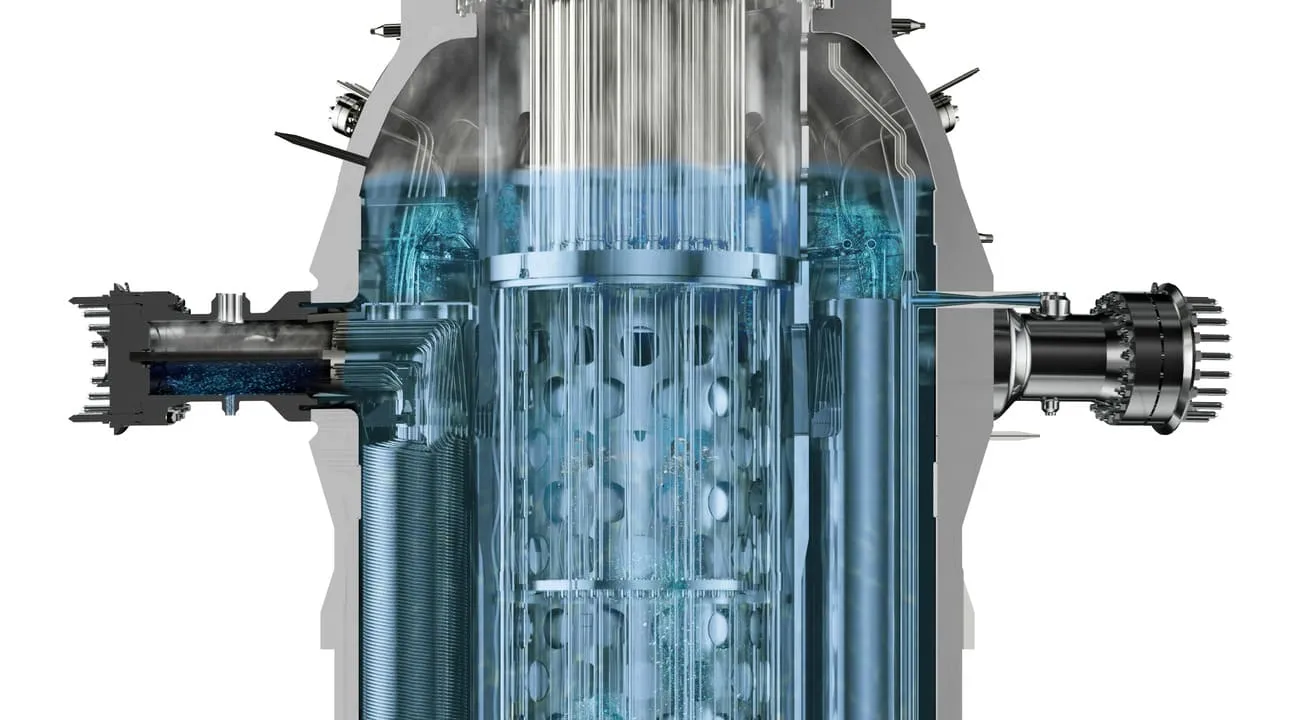

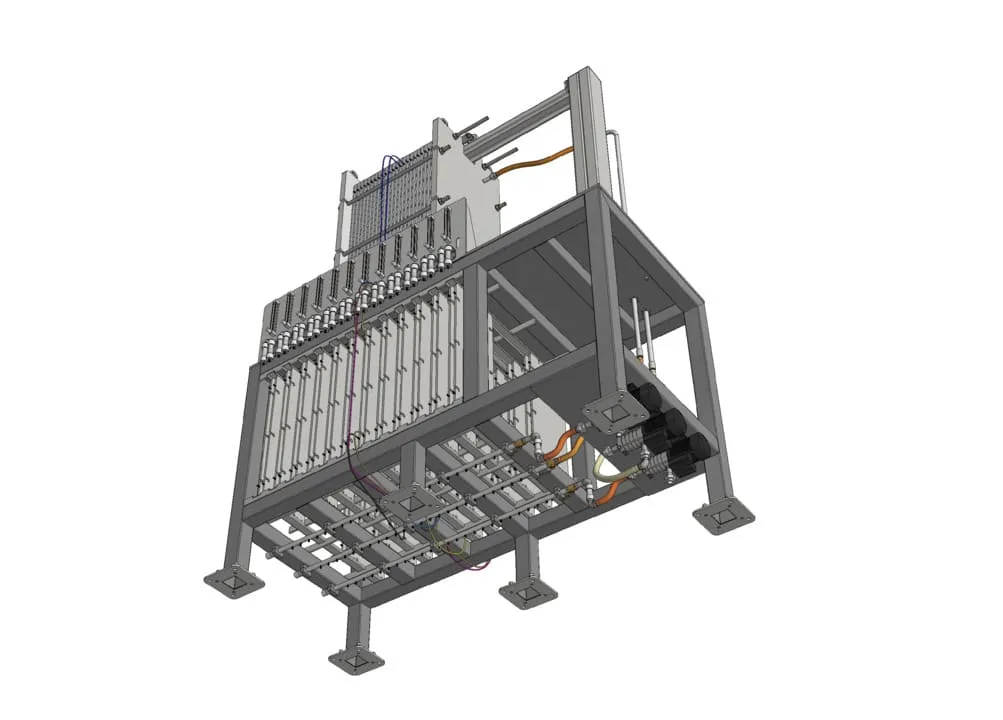

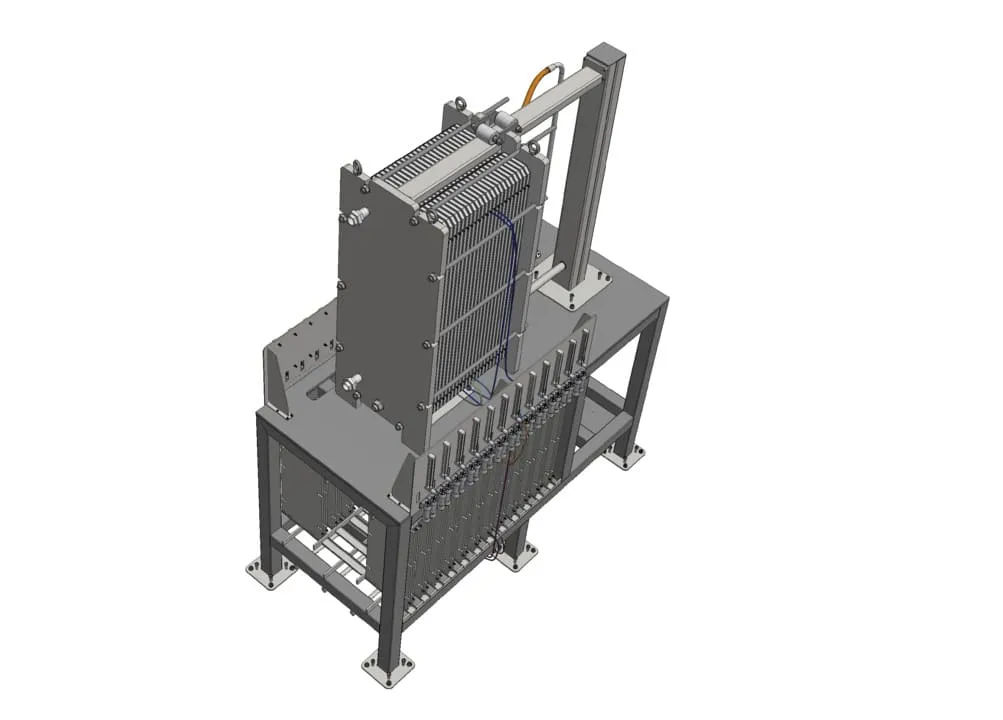

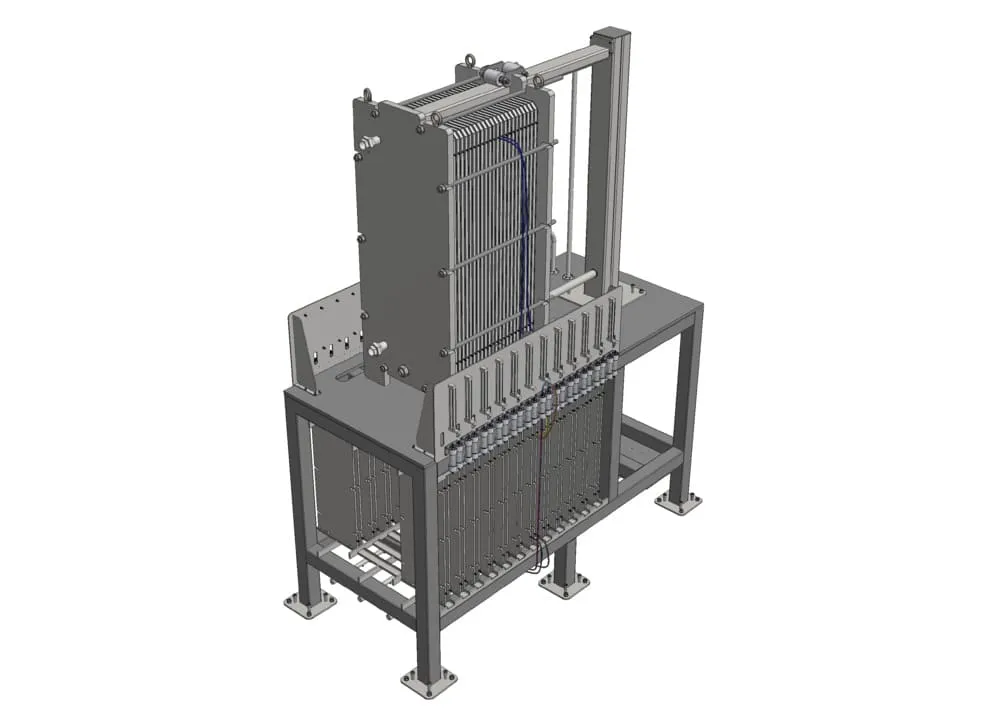

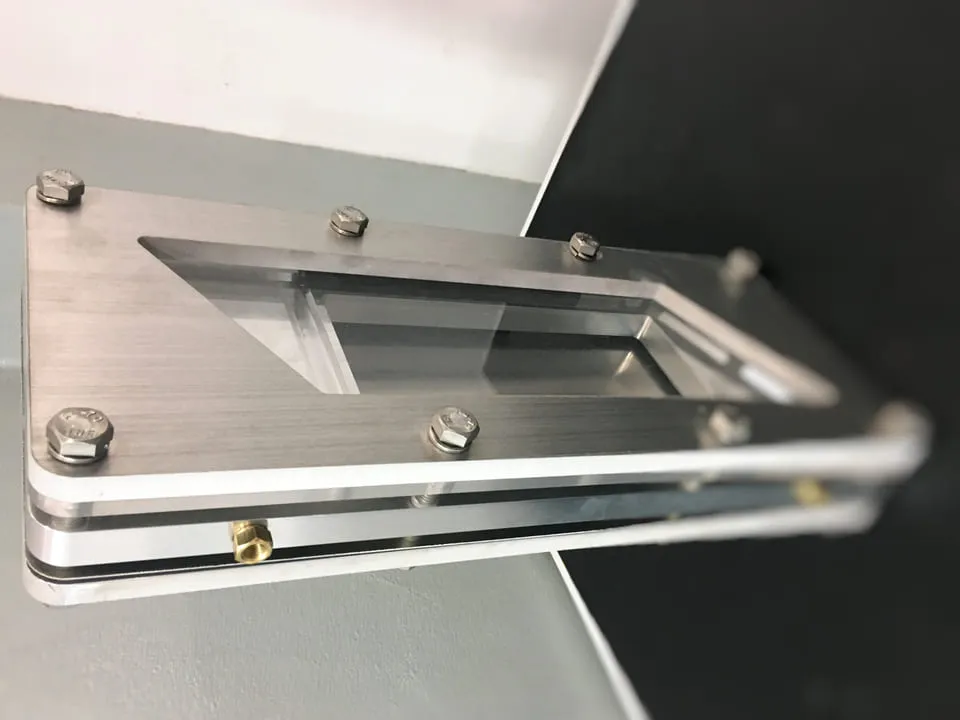

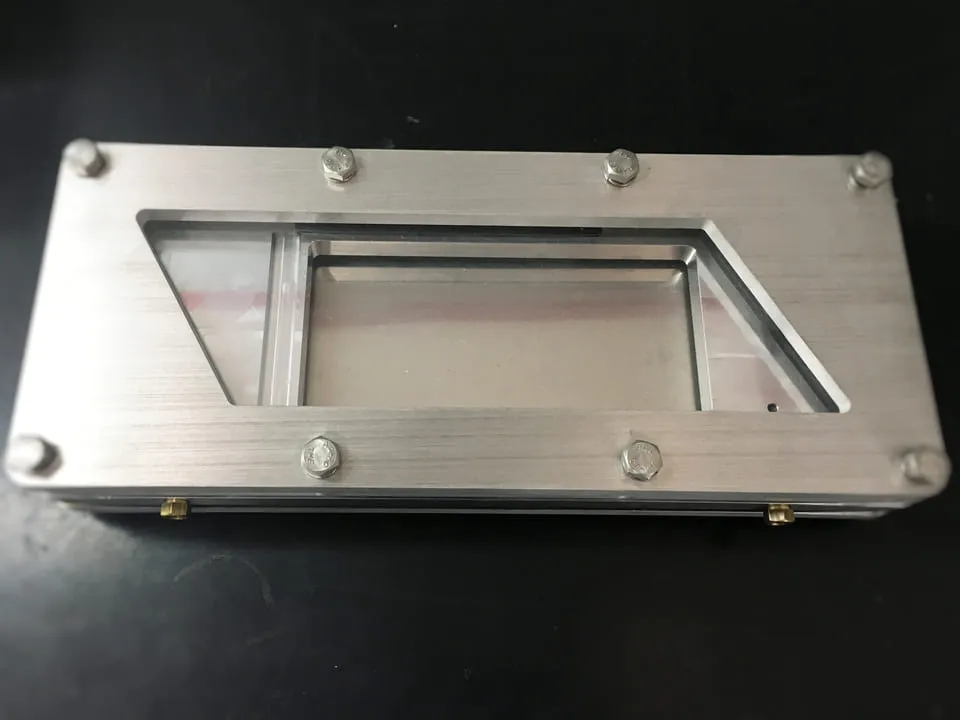

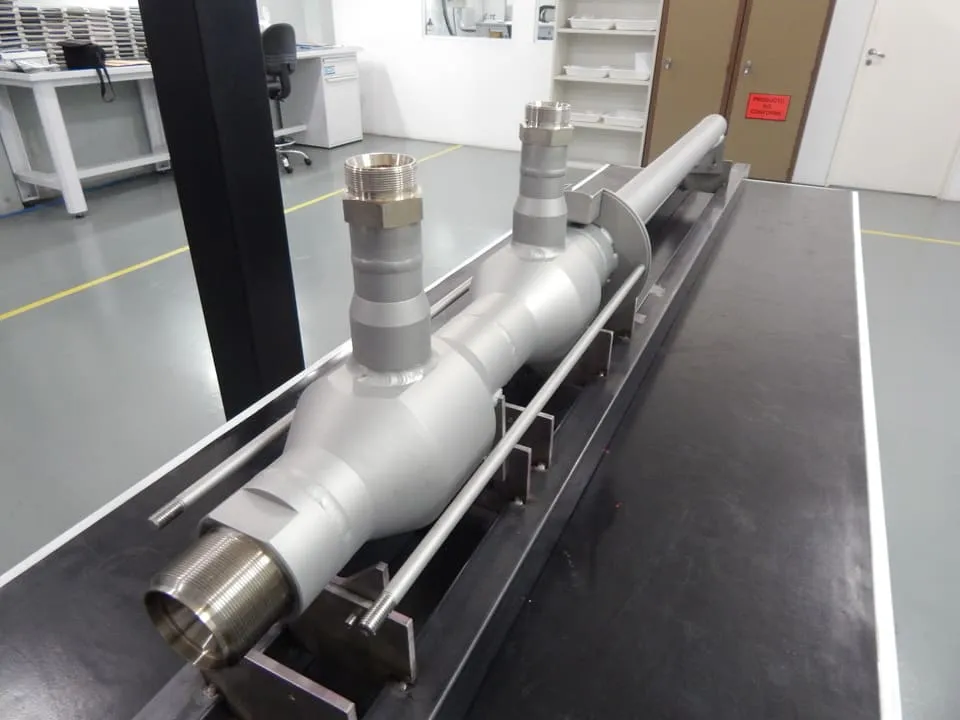

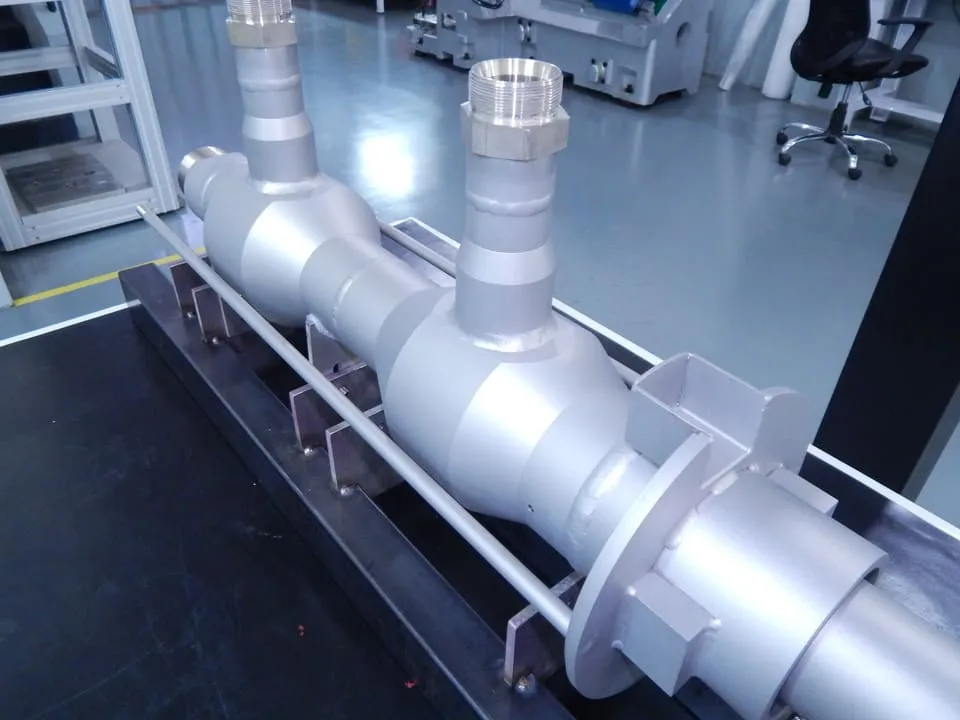

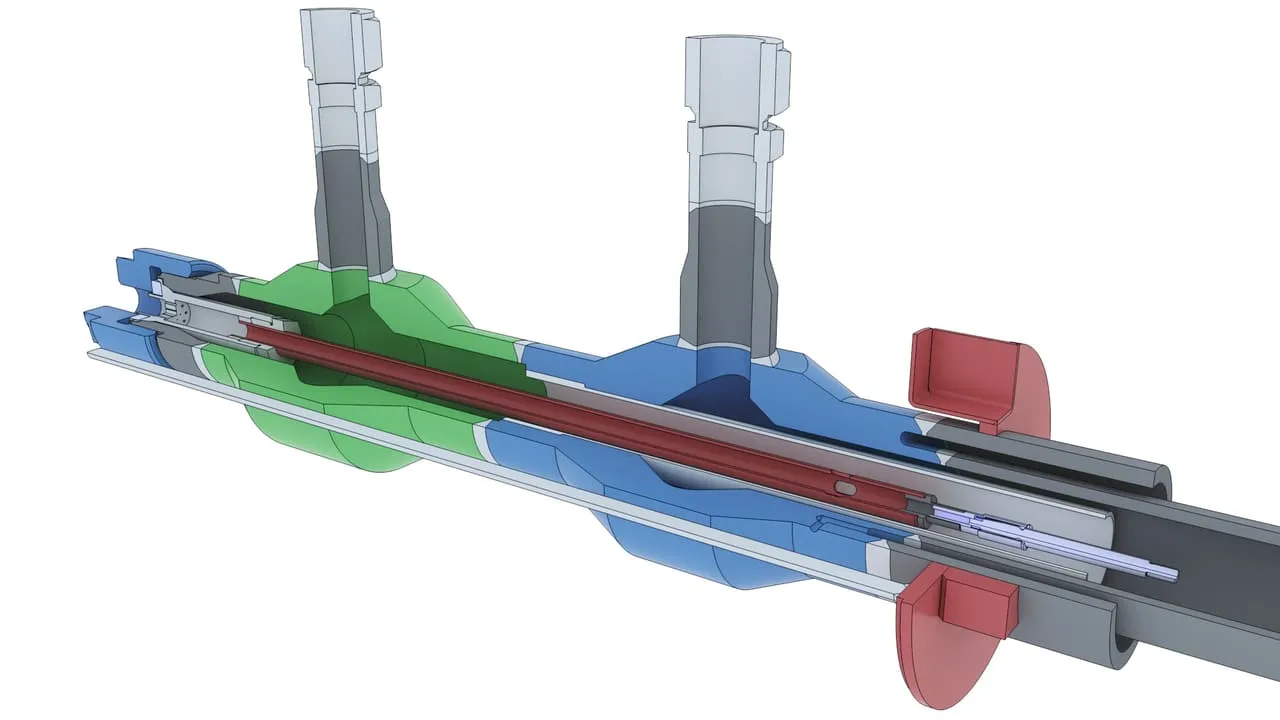

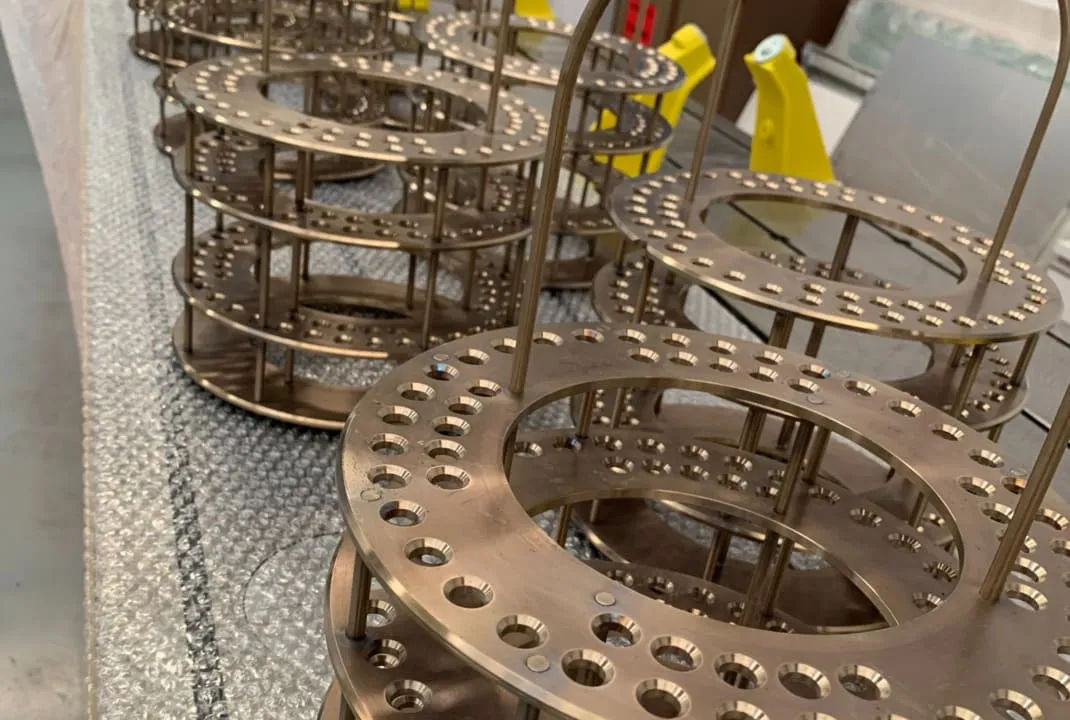

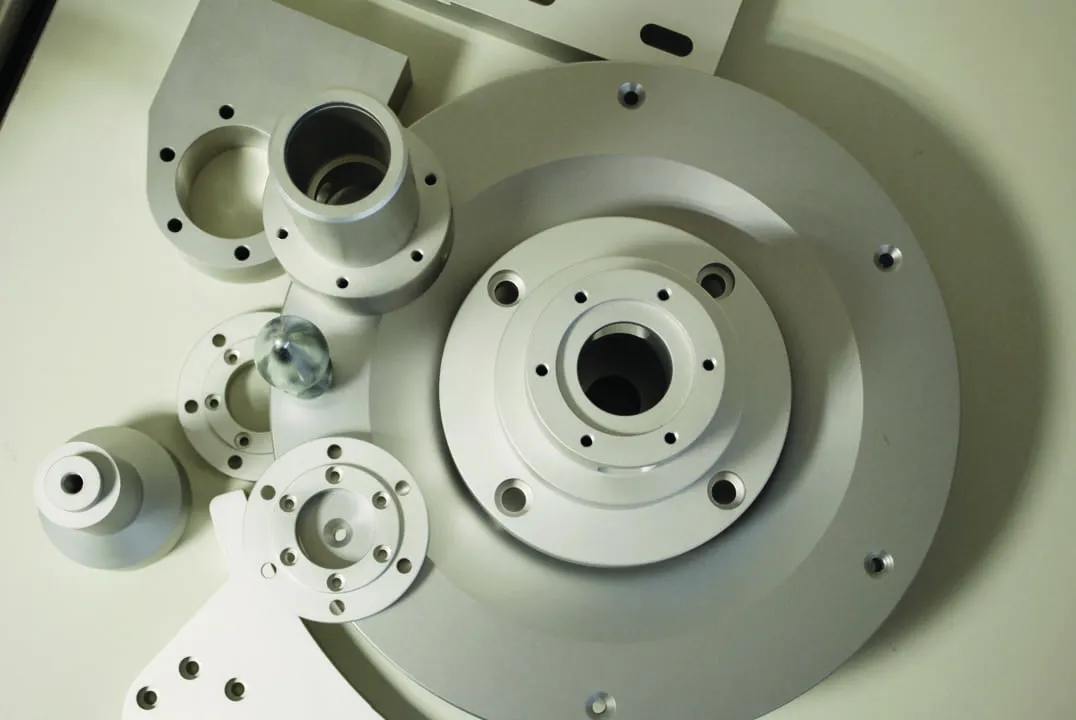

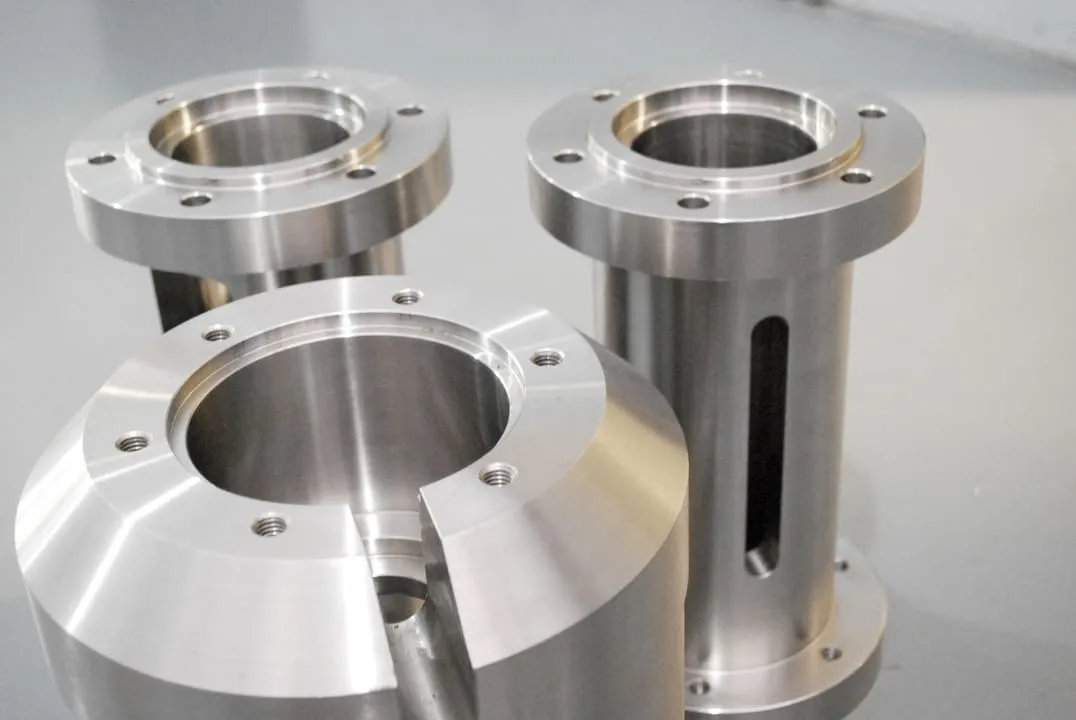

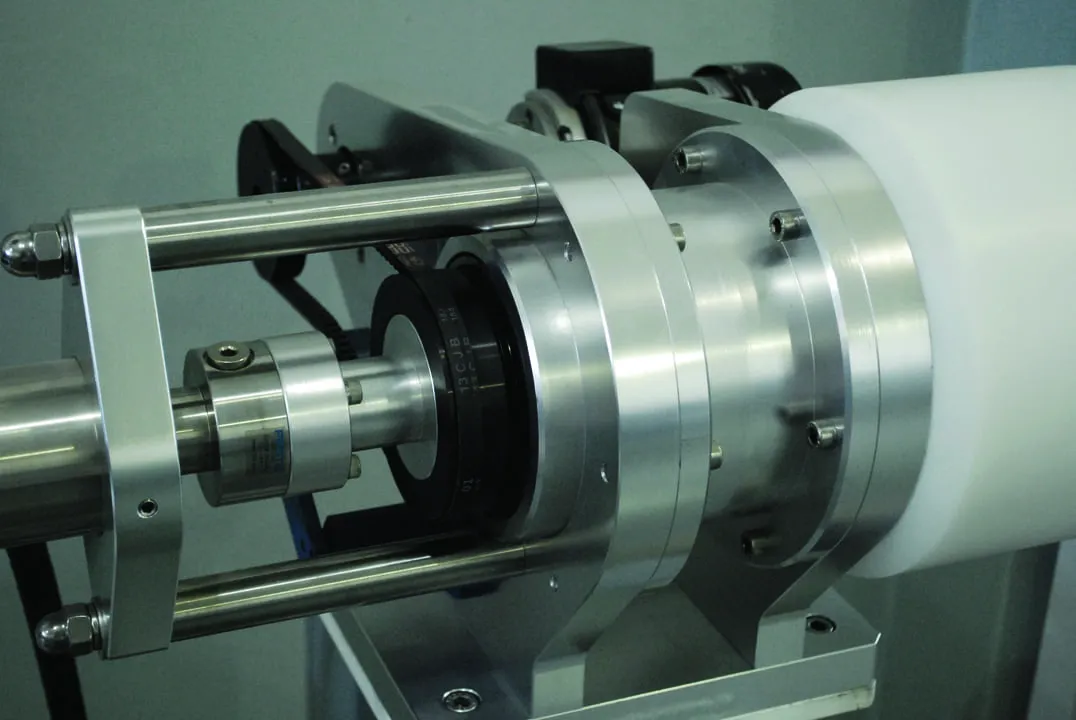

To manufacture radioactive Cobalt 60 sources, first Cobalt 59 slugs must be made from 99.7% pure Cobalt metal powder. Then, these Co59 pellets are introduced into the core of a nuclear reactor to be bombarded by the neutron flux- produced by nuclear fission, thus acquiring an additional neutron and becoming Cobalt 60. NUCLEARIS is the only company in Latin America to set up the first Cobalt 59 Slugs manufacturing plant for nuclear use. These Cobalt slugs are currently being exported all over the world through DIOXITEK S.A- a state-owned company in Argentina. The radioactive Cobalt isotope with atomic weight 60 is an element that constantly emits radiation with a rate of decay. This decay is accompanied by the emission of high energy radiation known as Gamma Rays which are used to sterilize medical devices and implants, perform cancer treatments, sterilize food, disinfect fruits, vegetables and grains, inertization treatment of sewage sludge and many other industrial applications.